About

Indika is an idea that grew out of our love of India’s creative traditions and our interest in social welfare.

We are connected with a handful of organizations around India that work to bring employment to artisans and keep alive traditional skills.

These organizations are focused on ecological awareness and self sustainability. In the face of harsh climates and natural disasters they push boundaries socially, economically and technologically in the work that they do. The unique nature of their lives can be felt in the things they produce.

Part of our philosophy involves buying what is offered for sale – never dictating to the artisans what should be produced for the western market. You will find that the items we offer have a distinctive quality.

We feel this is due to the fact that they are created in an environment so completely different from ours – in this lies their beauty.

Thank you for looking at our store.

– Travis, Farinaz, Aisha

At the Bandhniwalla’s…

Each time I visit our little coastal town of Porbandar, my mother and I make a pilgrimage to the shop of our Bandhniwallah in our local market. White gadlas (futons) on the cool stone floor, a table fan recirculating the early evening sea breeze. Chai is ordered and we sip from our glasses as bundles of bandhni odhnis (scarves) and sarees are pulled from the shelves, and we are surrounded by silk and cotton. Each piece unique in its intricate patterns of bandhni and its colour combinations.

I delight in the familiar of that kind of shopping. Having lived in north America for about 22 years now, I relish what I once took for granted. Taking my shoes off at the entrance to the shop, sitting cross-legged on the floor, glass of chai in my hand, looking through piles of fabric.

I left India in 1992. Each time I returned to visit, after a gap of a year or two, I found more of the crafts that I had grown up with, fading. A machine can easily stamp dots on fabric, so bandhni was fast being replaced by machined imitations. The skill of fine embroidery and especially detailed mirror work was virtually lost, as large aabla-mirrors covered more fabric and the hurried large-stitch embroidery could be worked by minors. Royalty once patronized and sponsored these crafts; since Indian independence in 1947, and since the abolition of Privy Purses in the early 1970s, these patrons couldn’t support artisans. With mechanization keeping up with the western demand for Indian products, the work of hands became almost redundant. Block printing, appliqué work, the ancient craft of bell making … detailed work that took time, took the care and knowledge passed down through generations of proud craftspeople… by the late 1990s this traditional work was simply on the verge of dying out.

Working to reverse this were a handful of philanthropists and entrepreuners. Instrumental among these were: Chandaben Shroff who founded Shrujan, Rachel Singh and her husband Pritam Singh who founded Anokhi, Bunker Roy who founded the Barefoot College.

My husband, Travis, and I started Indika in 2001, when our daughter, Aisha, was 11 months old. Those were days when people were hardly aware of the concept of fair trade, often confusing it with Free Trade! Fourteen years later, we are glad to see the educated awareness with which people now make spending decisions. Handmade crafts are being revived, the artisans are being empowered by fair wages, and their skills are recognized again.

Diwali Pujas

I have always loved the noisy festival of Diwali. Festival of lights and fireworks, celebrating the welcome of Lord Ram after fourteen years of exile.

Diwali day at our home in Porbandar always begins with one of my favourite pujas (rituals): the Lakshmi Puja, honoring the women (the ‘Lakshmis’ or the ‘goddesses of wealth’) of the household.

Then lunch and a rest from the heat of the afternoon sun.

In the evening, we all dress up and head to my father’s office for the “Office” Puja.

Traditionally, this was for men only as women didn’t work in the office. I remember watching as my brother sat with my father and grandfather, writing ‘good luck’ in the office ledgers, as part of the puja ritual. Times have changed. It is with pride that I see my daughter and niece now take part in this puja!

The front pages of the red, stitched, cloth-bound ledgers are splattered with red kum-kum, and turmeric for prosperity and fortune. Bamboo pens are dipped into inkwells to scrawl blessings. All new ledgers that will be used in the year ahead are decorated this way. The pages are pleated lengthwise to make columns for use in accounting.

Paan leaves with marigolds, cashew nuts, almonds, nutmeg, cardamom, and turmeric root are also placed on the books, each of those items signifying aspects of prosperity, clarity and other good business traits!

The bottom of a silver tray is lined with red kum-kum paste. With a matchstick, somebody draws an auspicious design in the kum-kum. Camphor is lit in the center and the tray is passed around for donations that are then given to the needy.

The puja is sombre and quiet. Its end is heralded by loud loud fireworks! Then a local band strikes up with blaring music, and the true celebrations for the evening begin!

This is how every fall, the new fiscal year begins for us in Porbandar.

Janmamad Salemamad Luhar, Bell Maker from Kutchch

The Rann of Kutchch. A desert in northern Gujerat on the west coast of India, that is desert for half the year, and is flooded for the other half of the year! There are vast regions of scrubby tree growth and sparsely populated areas. The gypsy tribes who once grazed cattle here, and later settled in villages, still retain their traditional customs and wear their elaborately embroidered and decorated clothes as they go about their daily tasks.

Janmamad Luhar is a traditional bell-maker in this region. He practices a craft that was passed down through several generations, as far back as they can remember! Bell makers then crafted bells for cattle. The lore goes that a goat-herder could tell which of his animals was missing by the unique sound of its bell!

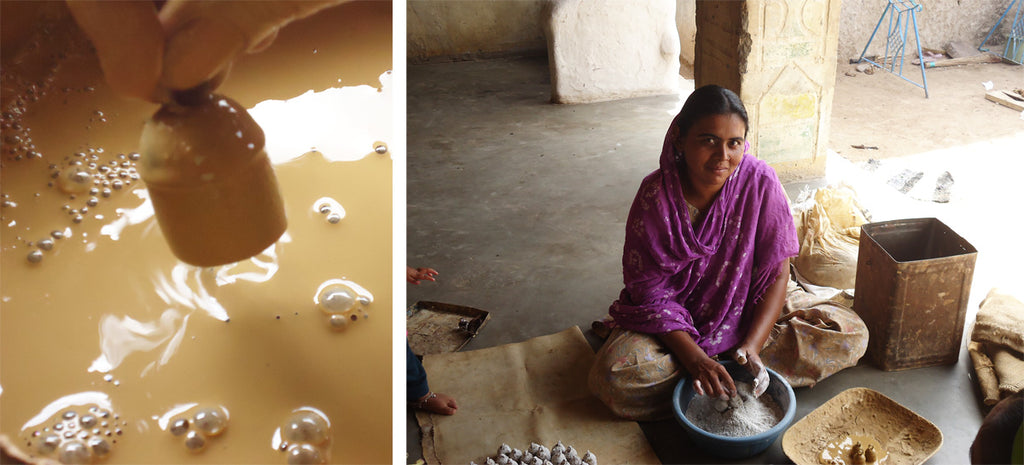

The bells all start out as flat sheets of recycled steel. The steel is then beaten and shaped into cylinders and and joined, without any welding at the seams! The shaped bells are dipped into a copper solution.

The women make a dough out of clay and coat the copper-dipped bells with the dough to protect the metal during firing.

Kilns are made in the desert sand, and the bells are fired. The steel and copper anneal to form bronze.

After the firing, the clay is removed; then the tuning process begins. Each bell is individually hand-tuned. From the largest bell, to the smallest bell, to every bell in every chime…. each is carefully tuned to perfection.

It is the combination of the firing and the tuning that give these bronze bells their unique patina and their mesmerizing tone.